Description

Failure of external piping scenario

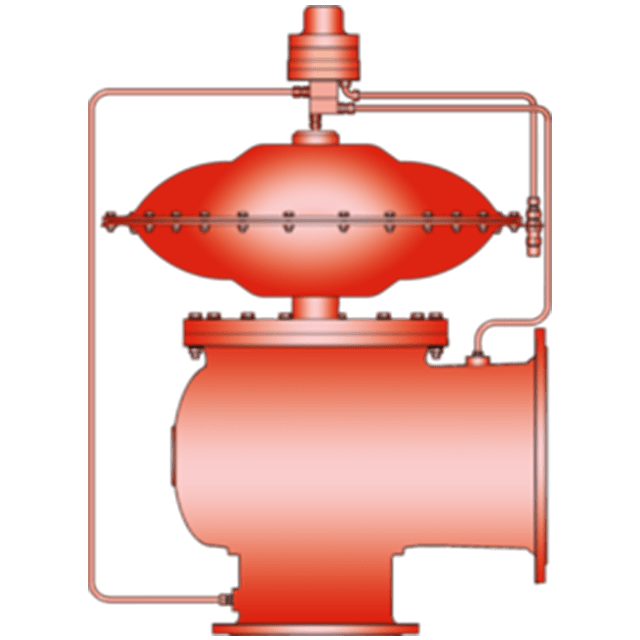

Decades of experience in manufacturing pilot-operated pressure/vacuum relief valves, our expertise in computer-optimized design, and our extensive test facilities form the basis for the development of the most powerful vent valves. The storage of cryogenic liquified gases makes special demands on the venting devices required for tank equipment.

These valves are designed in accordance with the applicable standards and the operating point of the various products in the process. Pilot-operated pressure and vacuum relief valves - if necessary, used in combination with separate pallet valves - ensure that maximum allowable operating pressures of the tank are not exceeded.

Vacuum scenario

Vacuum scenario

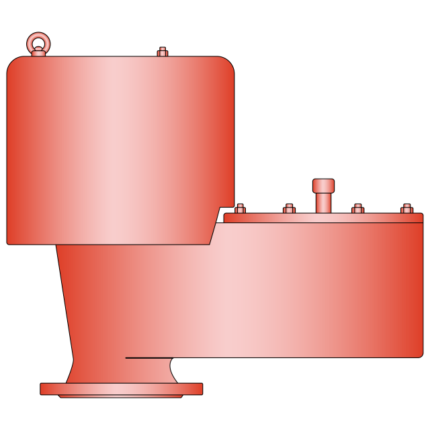

So-called in-tank valves (actuator operated shut-off valve with "fail close" function) are used mainly in cryogenic tanks where the tank wall or the bottom is penetrated by the discharge pipe.

In the event of malfunctions, in-tank valves are used as a shut-off valve to minimize the spread of hazards due to product spills.

Pressure scenario

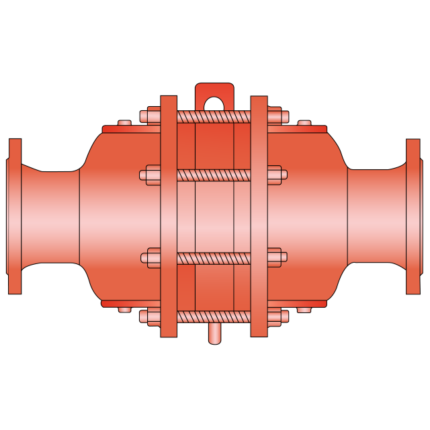

Pilot-operated pressure and vacuum relief valves achieve maximum tightness up to the set pressure. Spring-loaded and magnet-loaded pilots are the main valve's reliable switching components. Optional backflow preventers, test connections, and test equipment are available for functional inspections at the point of installation. Using shuttle valves allows the operation of valves in AND / OR mode and to carry out maintenance at the point of use.

+7(727) 266-56-23

+7(727) 266-56-23 info@promex-world.com

info@promex-world.com