Description

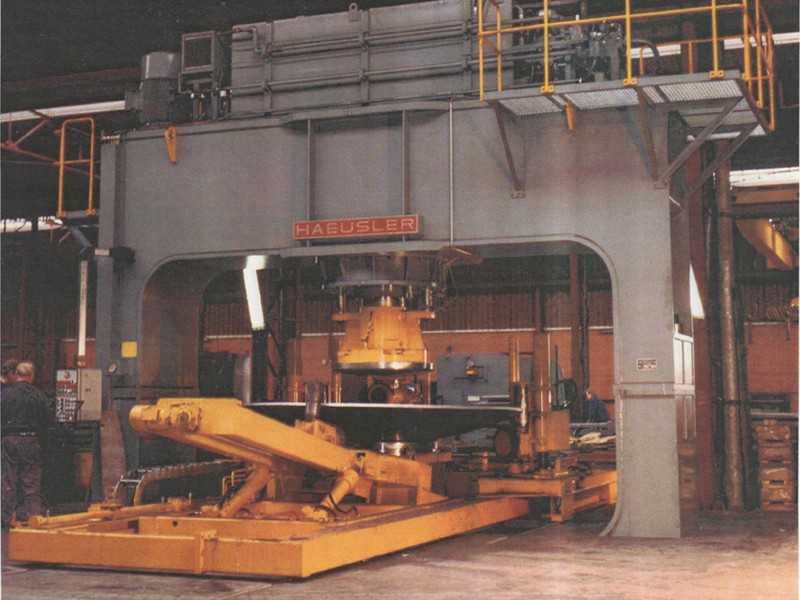

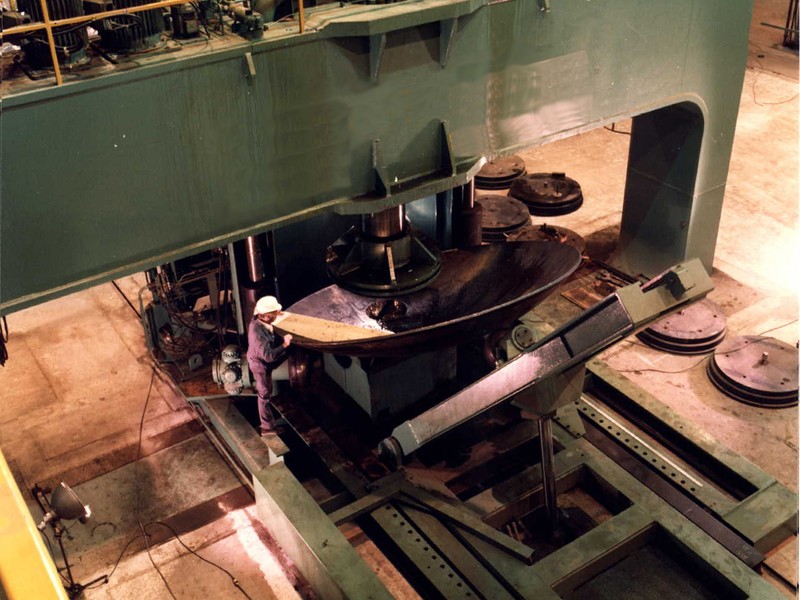

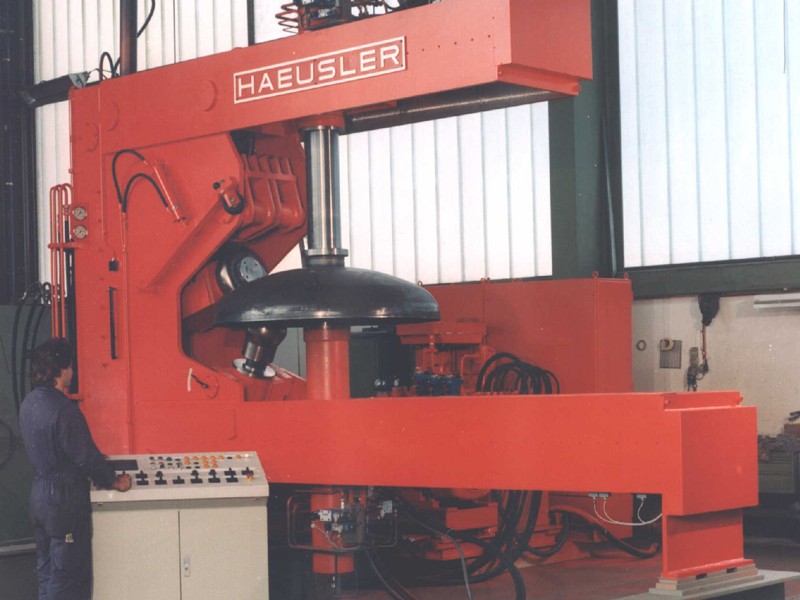

For the production of heads and tanks, HAEUSLER offers HKP punching presses and HBM edge bending machines in all sizes.

On the HKP press, the bottoms are clamped by two molds. Since the size of the interchangeable molds is limited, stamping occurs through repeated movements of the press, changing the position of the bottom blank between feeds. For these purposes, the stamping press is equipped with a manipulator that automatically moves the workpiece between the expanded molds of the press until the entire workpiece has been processed.

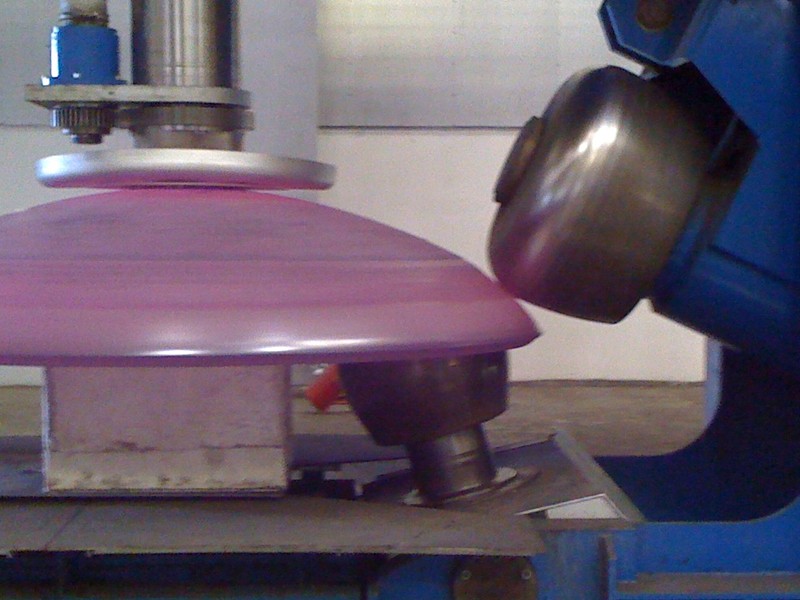

Next, the edges are processed using an RBM edge bending machine and the workpiece is given its final shape.

HAEUSLER edge bending machines perform any task: bending cold and hot sheet metal, with or without a central hole. With the quick-change forming rolls of these machines, you can achieve any hem radius.

+7(727) 266-56-23

+7(727) 266-56-23 info@promex-world.com

info@promex-world.com